Product categories

News center

Contact us

- Add: 2002, Block B, Zheshang Square,Langfang City, Hebei

- Tel: 010-88362920

- Fax: 010-88362920

- Email: linayang@hksifiri.com

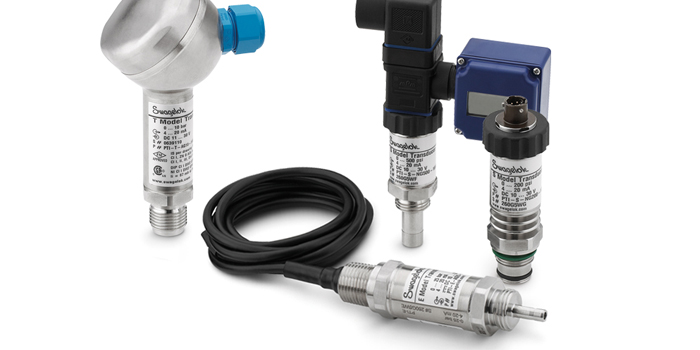

Pressure Transducers

Swagelok pressure transducers provide accurate electronic pressure monitoring for industrial applications. Offered in a wide range of pressure ranges, process connections, electrical connectors, and output signals to support a wide range of customer requirements.

Industrial Pressure Transducers—S Model (Standard Industrial), E Model (Explosion Proof), and T Model (Intrinsically Safe)

All models feature stainless steel construction. A wide variety of pressure ranges, process connections, electrical connectors, output signals, and options enable configurations customized to meet system requirements.

- Thin film and piezoresistive sensor technology help provide repeatability, reliability, and stability.

- Available in flush diaphragm version for use with viscous fluids and slurries

- Accuracy 0.5 % of span limit point calibration (0.25 % of span best fit straight line)

- Broad selection of pressure ranges, engineering units in psi, bar, MPa, kg/cm2, and kPa.

- Pressure references of compound, gauge, or absolute

- Process connections; Swagelok tube adapter, NPT, RG, RJ, ISO7 taper

- Flush diaphragm: G1/2B EN or G1B EN

T Model: Intrinsically Safe Pressure Transducer

The Swagelok T Model is engineered for use in industrial pressure measurement applications where intrinsically safe ratings are required, such as hazardous environments or media, including gases, vapors and dust. Products are approved as intrinsically safe, FM and CSA, when used with an intrinsically safe associated apparatus.

- Adjustable zero and span

- Available in a field-case version for use in corrosive or washdown environments

View and purchase our most widely used products.

Discover more about how Swagelok products can work for you. Browse our catalogs or locate a sales and service center.

"Safe Product Selection: The complete catalog contents must be reviewed to ensure that the system designer and user make a safe product selection. When selecting products, the total system design must be considered to ensure safe, trouble-free performance. Function, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibilities of the system designer and user.

|